文章转自ADI官网,版权归属原作者一切

Capacitive sensing user interfaces are desirable features for the latest consumer electronic products; from cell phones to media players to satellite navigation systems, the trend to enhance the human interface is evolving. The principle of a user touch causing a change in capacitance to activate a switch is well understood, but implementing a PCB sensor design with proper shielding and routing poses a challenge for hardware designers.

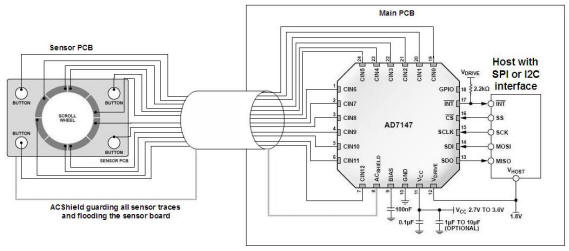

The change in capacitance in response to a finger touch is only a fraction of a picofarad, so tiny parasitic capacitances seen by the sensor or sensor traces reduce the dynamic range of the capacitive sensor controller. In addition, inadequate sensor shielding can present coupling paths that create a noisy response, degrading the SNR achievable by the sensor and decreasing the resolution of the user interface. Designed for use with single-electrode capacitance sensors implementing functions such as buttons, scroll bars, and wheels, the AD7147 CapTouch™ controller provides an active ACShield signal that minimizes the problem of parasitic capacitance, remote sensor connection, sensor routing and shielding of the capacitive sensors.

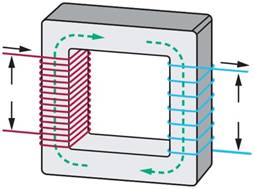

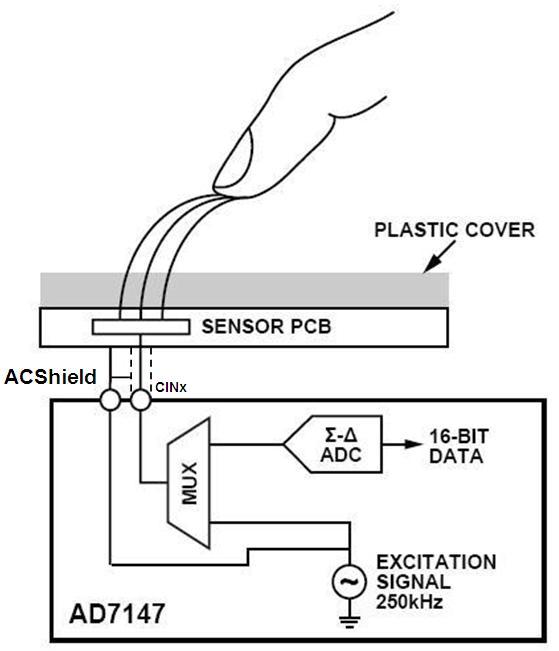

A common configuration for capacitive sensing is to have the sensor controller on the main board, with the sensors patterned on a separate sensor board, as shown in Figure 1.

The sensor board is often connected to the main board by a cable. This separation prevents high-speed signals from coupling onto the capacitive sensors and reduces the large parasitic capacitance caused by ground planes. In addition, the sensors are the human interface, and sometimes must be remote from the main board. The sensors can be implemented on FR4 or ultra thin transparent ITO material.

The AD7147 works by alternately switching the capacitive sensor between an excitation signal and a capacitance-to-digital converter (CDC), as shown in Figure 2.

The advantage of the ACShield signal is that the sensors and the sensor traces can be shielded by a signal that is in phase with the excitation on the sensors. Eliminating the potential between shield and sensor/sensor traces also eliminates the capacitance. Therefore, to minimize parasitic capacitance and noise coupling, the ACShield signal can be flooded on the sensor board and used as a guard signal along all sensor traces. Use of the ACShield signal in the AD7147 allows a separation of up to 60 cm between controller and sensor(s).

Analog Devices provides a complete solution in capacitive sensing, including the controller, evaluation tools, sensor design libraries, and software for the host microcontroller.