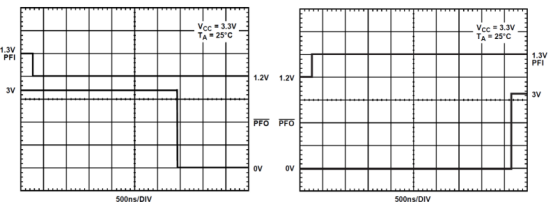

一个PIC16F877A单片机有1个16位守时器TIMER1,咱们用来控制8个舵机(即次序脉冲输出),这样一个单片机就能够操控8个舵机。用8个IO口来操控舵机,舵机操控的信号周期为20mS,而正脉冲最大只要2.5mS,这样有17.5mS是空的。能够选用这种办法:在RD0口输出一个0.5~2.5mS的脉冲,操控一号舵机。完成后,用端口RD1口输出别的一个脉冲,操控2号舵机,就这样下去…..在一号舵机需求第二个脉冲之前,能够输出 20/2.5=8个脉冲,能够用来操控8个舵机,当然,需求用8个IO口。可是一般来说不可能正好有8个2.5mS的脉冲来填满20mS,这样就需求对输出脉冲的总宽度进行累加补偿,然后再用低电平填满20mS中剩余的时刻。一个周期让timer1作业8~9次,前8次每次依据不同舵机的脉宽要求进行守时,每次都对不同的IO口输出脉冲.第九个守时是用来填满20mS的剩余时刻的. 每个口在输完脉冲后,置0 ,然后单片机就不必管他,能够进行下一个IO口的脉冲输出了. 这样一个单片机次序对8个IO口进行脉冲输出. 尽管每个舵机的脉冲时刻有一点推迟,可是不超越20mS,这关于舵机这种低速运转器材来说是彻底感觉不出来的。仿真如下图:

下面就用这种办法进行编程。

#include

unsigned char servo_angle_H[8];

unsigned char servo_angle_L[8];

unsigned char compensate_TL;

unsigned char compensate_TH;

unsigned char p;

void set_servo (unsigned char angle0,unsigned char angle1,

unsigned char angle2,unsigned char angle3,

unsigned char angle4,unsigned char angle5,

unsigned char angle6,unsigned char angle7)

{

unsigned int temp,temp0,value[8];

unsigned char i;

for(i=0;i<8;i++){

servo_angle_H[i]=64468/256;

servo_angle_L[i]=64468%256;

}

compensate_TL=50268%256;

compensate_TH=50268/256;

temp = angle0+angle1+angle2+angle3+angle4+angle5+angle6+angle7;

value[0]=65068-(100*angle0)/9;

value[1]=65068-(100*angle1)/9;

value[2]=65068-(100*angle2)/9;

value[3]=65068-(100*angle3)/9;

value[4]=65068-(100*angle4)/9;

value[5]=65068-(100*angle5)/9;

value[6]=65068-(100*angle6)/9;

value[7]=65068-(100*angle7)/9;

for(i=0;i<8;i++){

servo_angle_H[i]=value[i]/256;

servo_angle_L[i]=value[i]%256;

}

temp0=46068+(100*temp)/9;

compensate_TL=temp0%256;

compensate_TH=temp0/256;

}

//主程序***********************************************************************

void main(void)

{unsigned int a;unsigned int b;

INTCON=0;

GIE=1;//;翻开总中止

PEIE=1;//;翻开外部中止使能位

TMR1IE=1;//;翻开TMR1中止

TRISD=0X00;

PORTD= 0X00;//脉冲波形开始状况

T1CON=0x01;//设置TMR1的操控字

TMR1IF=0;

unsigned char i;

set_servo (13,34,56,87,80,123,156,13);

while(1){;}

}

//中止服务程序*************************************************************

void interrupt timer1(void)

{

TMR1IF=~TMR1IF;

switch(p){

case 0:TMR1L=servo_angle_L[p];TMR1H=servo_angle_H[p];PORTD=0X01;

break;

case 1:TMR1L=servo_angle_L[p];TMR1H=servo_angle_H[p];PORTD=0B00000010;

break;

case 2:TMR1L=servo_angle_L[p];TMR1H=servo_angle_H[p];PORTD=0B00000100;

break;

case 3:TMR1L=servo_angle_L[p];TMR1H=servo_angle_H[p];PORTD=0B00001000;

break;

case 4:TMR1L=servo_angle_L[p];TMR1H=servo_angle_H[p];PORTD=0B00010000;

break;

case 5:TMR1L=servo_angle_L[p];TMR1H=servo_angle_H[p];PORTD=0B00100000;

break;

case 6:TMR1L=servo_angle_L[p];TMR1H=servo_angle_H[p];PORTD=0B01000000;

break;

case 7:TMR1L=servo_angle_L[p];TMR1H=servo_angle_H[p];PORTD=0B10000000;

break;

default:TMR1L=compensate_TL;TMR1H=compensate_TH;PORTD=0B00000000;p=0;

break;

}

p++;

}