文章转自ADI官网,版权归属原作者一切

Q: What is a capacitance sensor?

A: Capacitance sensors detect a change in capacitance when something or someone approaches or touches the sensor. The technique has been used in industrial applications for many years to measure liquid levels, humidity, and material composition. A newer application, coming into widespread use, is in human-to-machine interfaces. Mechanical buttons, switches, and jog wheels have long been used as the interface between the user and the machine. Because of their many drawbacks, however, interface designers have been increasingly looking for more reliable solutions. Capacitive sensors can be used in the same manner as buttons, but they also can function with greater versatility, for example, when implementing a 128-position scroll bar.

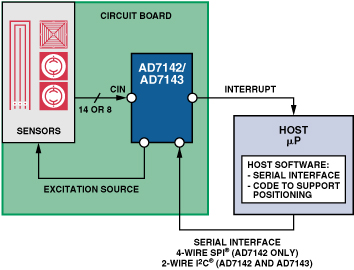

Integrated circuits specifically designed to implement capacitance sensing in human-machine interface applications are now available from Analog Devices. The AD7142 and the AD7143, for example, can stimulate and respond to up to 14 and eight capacitance sensors, respectively. They provide excitation to the capacitance sensor, sense the changes in capacitance caused by the user’s proximity, and provide a digital output.

Q: How does capacitance sensing work?

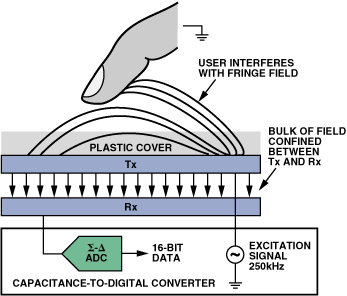

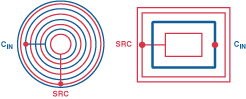

A: A basic sensor includes a receiver and a transmitter, each of which consists of metal traces formed on layers of a printed-circuit board (PCB). As shown in Figure 1, the AD714x has an on-chip excitation source, which is connected to the transmitter trace of the sensor. Between the receiver and the transmitter trace, an electric field is formed. Most of the field is concentrated between the two layers of the sensor PCB. However, a fringe electric field extends from the transmitter, out of the PCB, and terminates back at the receiver. The field strength at the receiver is measured by the on-chip sigma-delta capacitance-to-digital converter. The electrical environment changes when a human hand invades the fringe field, with a portion of the electric field being shunted to ground instead of terminating at the receiver. The resultant decrease in capacitance—on the order of femtofarads as compared to picofarads for the bulk of the electric field—is detected by the converter.

In general, there are three parts to the capacitance-sensing solution, all of which can be supplied by Analog Devices.

- The driver IC, which provides the excitation, the capacitance-to-digital converter, and compensation circuitry to ensure accurate results in all environments.

- The sensor—a PCB with a pattern of traces, such as buttons, scroll bars, scroll wheels, or some combination. The traces can be copper, carbon, or silver, while the PCB can be FR4, flex, PET, or ITO.

- Software on the host microcontroller to implement the serial interface and the device setup, as well as the interrupt service routine. For high-resolution sensors such as scroll bars and wheels, the host runs a software algorithm to achieve high resolution output. No software is required for buttons.

Q: What are the advantages of capacitive sensing?

A: Capacitance sensors are more reliable than mechanical sensors—for a number of reasons. There are no moving parts, so there is no wear and tear on the sensor, which is protected by covering material, for example, the plastic cover of an MP3 player. Humans are never in direct contact with the sensor, so it can be sealed away from dirt or spillages. This makes capacitance sensors especially suitable for devices that need to be cleaned regularly—as the sensor will not be damaged by harsh abrasive cleaning agents—and for hand-held devices, where the likelihood of accidental spillages (e.g., coffee) is not negligible.

Q: Tell me more about how the AD714x ICs work.

A: These capacitance-to-digital converters are designed specifically for capacitance sensing in human-interface applications. The core of the devices is a 16-bit sigma-delta capacitance-to-digital converter (CDC), which converts the capacitive input signals (routed by a switch matrix) into digital values. The result of the conversion is stored in on-chip registers. The on-chip excitation source is a 250-kHz square wave.

The host reads the results over the serial interface. The AD7142, available with either SPI®– or I2C®-compatible interfaces, has 14 capacitance-input pins. The AD7143, with its I2C interface, has eight capacitance-input pins. The serial interface, along with an interrupt output, allows the devices to connect easily to the host microcontroller in any system.

These devices interface with up to 14 external capacitance sensors, arranged as buttons, bars, wheels, or a combination of sensor types. The external sensors consist of electrodes on a 2- or 4-layer PCB that interfaces directly with the IC.

The devices can be set up to interface with any set of input sensors by programming the on-chip registers. The registers can also be programmed to control features such as averaging and offset adjustment for each of the external sensors. An on-chip sequencer controls how each of the capacitance inputs is polled.

The AD714x also include on-chip digital logic and 528 words of RAM that are used for environmental compensation. Humidity, temperature, and other environmental factors can affect the operation of capacitance sensors; so, transparently to the user, the devices perform continuous calibration to compensate for these effects, giving error-free results at all times.

One of the key features of the AD714x is sensitivity control, which imparts a different sensitivity setting to each sensor, controlling how soft or hard the user’s touch must be to activate the sensor. These independent settings for activation thresholds, which determine when a sensor is active, are vital when considering the operation of different-size sensors. Take, for example, an application that has a large, 10-mm-diameter button, and a small, 5-mm-diameter button. The user expects both to activate with same touch pressure, but capacitance is related to sensor area, so a smaller sensor needs a harder touch to activate it. The end user should not have to press one button harder than another for the same effect, so having independent sensitivity settings for each sensor solves this problem.

Q: How is the environment taken into account?

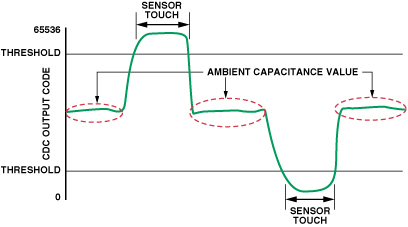

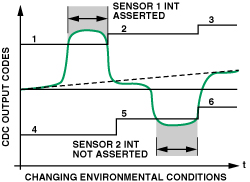

A: The AD714x measures the capacitance level from the sensor continuously. When the sensor is not active, the capacitance value measured is stored as the ambient value. When a user comes close to or touches the capacitance sensor, the measured capacitance decreases or increases. Threshold capacitance levels are stored in on-chip registers. When the measured capacitance value exceeds either upper or lower threshold limits, the sensor is considered to be active—as shown in Figure 4—and an interrupt output is asserted.

Figure 4 shows an ideal situation, where the ambient capacitance value does not change. In reality, the ambient capacitance changes constantly and unpredictably due to changes in temperature and humidity. If the ambient capacitance value changes sufficiently, it can affect the sensor activation. In Figure 5, the ambient capacitance value increases; Sensor 1 activates correctly, but when the user tries to activate Sensor 2, an error occurs. The ambient value has increased, so the change in capacitance measured from Sensor 2 is not large enough to bring the value below the lower threshold. Sensor 2 cannot now be activated, no matter what the user does, as its capacitance cannot decrease below the lower threshold in these circumstances. A worse possibility is that the ambient capacitance level continues to increase until it is above the upper threshold. In this case, Sensor 1 will become active, even though the user has not activated it, and it will remain active—the sensor will be “stuck” on—until the ambient capacitance falls.

On-chip logic circuits deal with the effects of changing ambient capacitance levels. As Figure 6 shows, the threshold levels are not constant; they track any changes in the ambient capacitance level, maintaining a fixed distance away from the ambient level to ensure that the change in capacitance due to user activation is always sufficient to exceed the threshold levels. The threshold levels are adapted automatically by the on-chip logic and are stored in the on-chip RAM. No input from the user or host processor is required.

Q: How is capacitance sensing applied?

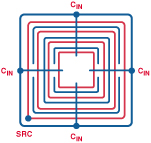

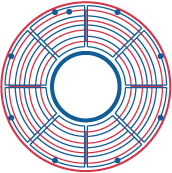

A: As noted earlier, the sensor traces can be any number of different shapes and sizes. Buttons, wheels, scroll-bar, joypad, and touchpad shapes can be laid out as traces on the sensor PCB. Figure 7 shows a selection of capacitance sensor layouts.

Sensor

| Button |

|

| 8-Way Switch |

|

| Slider |

|

| Wheel |

|

|

Keypad

声明:本文内容来自网络转载或用户投稿,文章版权归原作者和原出处所有。文中观点,不代表本站立场。若有侵权请联系本站删除(kf@86ic.com)https://www.86ic.net/qianrushi/ruanjian/44396.html

|